Introduction:

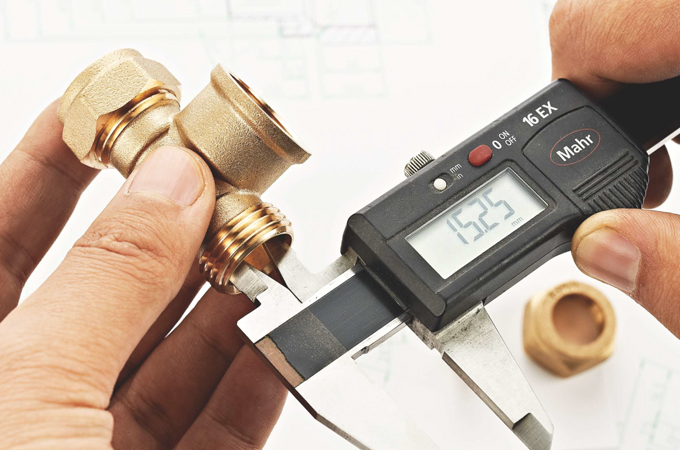

Name: Compression Fitting for Copper Tube

Nominal Pressure: ≤1.6MPa

Applicable Temperature: -20°C ~110°C

Applicable Medium: oil, water, gas and other non corrosive or corrosive medium

Tubing:φ6~φ54 Copper Tube

Material:

1. Body: CW617N

2. Metal ring: H62

3. Nut:CW617N

Certification:

Hongdaer compression fittings obtained WRAS certification.

Surface treatment:

Natural brass/Chrome plated

Installation Method:

1. Saw off appropriate length of seamless copper tube and remove burrs from the tube ends. Keep the vertical of the tube end and axis, the tolerance of the angle should be less than 0.5°. If the tube needs to be bent, the length of the straight line from the end of the pipe to the curved part should be at least 3 times the length of the thread of the fitting.

2. Sheathe the seamless copper tube to the metal ring and Nut. Pay attention to the direction of the metal ring and Nut.

3. Apply lubricating oil to the pre-assembled threads and card sets, insert the copper tube into the joint body (the tube must be inserted at the end), and tighten the nut by hand.

4. Tighten the nut until the metal ring is stuck on the tube, and the turning point can be felt (pressure point) by tightening torque.

5. After the pressure point is reached, tighten the nut 1/2 circle.

6. Remove the pre-installed connector body and check the edge of the insertion nut. It can be seen that the projection belt must fill the space at the end of the metal ring.The nut can be rotated slightly, but not axially.

7. During the final installation, the thread of the actual installation joint body is coated with lubricating oil, and the tightening force can be felt by pressing the nuts and screws until the tightening force increases.Then tighten the installed 1/2 circle.

TYPICAL INSTALLATION: